Construction

Filament custom carbon fibre frames are tailor-made for individual riders at our workshop in Worcestershire, England.

The frames are made from carbon tubes which are cut, bonded and reinforced with carbon joints. This process allows a wide range of sizes and custom geometry options.

Here's a step-by-step look at the process.

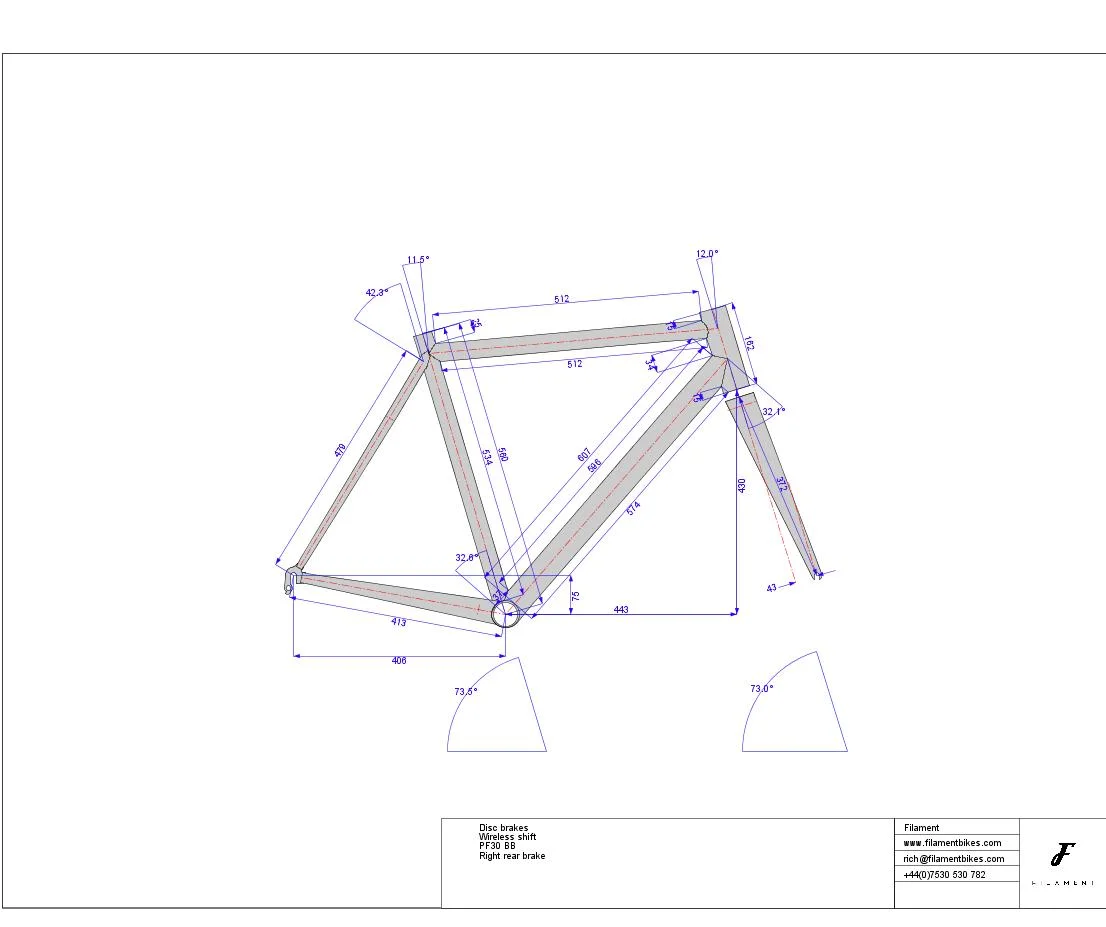

The construction process begins with the frame drawing which has all the dimensions required for cutting the tubes and setting the fixture.

The choice of bottom bracket formats is titanium threaded BSA, T47, carbon BB386 EVO or PF30

A complete carbon tube is used for press fit to ensure the bearings are held concentric and parallel. The laminate is balanced and symmetrical and undergoes a controlled cure cycle on a precision mandrel mould to ensure circularity (roundness). It has a thick laminate wall for stiffness to hold the bearings rigidly when riding.

A precision GO/NOGO gauge is used to check each press fit frame.

We all like a quiet bike.

The carbon bottom bracket shell is made by wrapping prepreg carbon over a stainless steel mandrel mould.

The carbon tubes are precisely cut using diamond tipped tools.

The cut tube set.

The tubes are held in the adjustable fixture and initially bonded together using a structural adhesive.

The smooth transitions between the tubes are made by hand. This provides the foundation for the next step.

The tube junctions are wrapped with many layers of prepreg carbon fibre to make a high strength reinforced joint.

The uncured frame is consolidated in a vacuum envelope which is placed into the oven to cure the prepreg.

Final machining operations after cure include cutting the slot of the the seat tube.

The completed frame is ready for paint.

The finished frame with its custom paint scheme.